Vital Plastics

From pellet to product, you can TRUST THE VITAL DIFFERENCE!

Vital Plastics is a premier plastic injection molding company with full-service contract assembly solutions. We specialize in high-volume production, supported by a wide range of molding equipment with capacities from 30 to 400 tons. From prototyping to full-scale manufacturing, our mission is to exceed your expectations in both molding and assembly.

Our operations are built around a Cellular Manufacturing model, ensuring consistent quality and attention to detail across every injection-molded component. With a dedicated assembly team of over 250 professionals, we offer flexible options including automated, semi-automated, and manual assembly to meet the specific needs of your product.

Strategically located East of Minnesota’s Twin Cities metro area on Interstate I-94, Vital Plastics, Inc. is an industry leader dedicated to delivering exceptional customer service, expert design and engineering support, and high-quality parts on time, every time.

With nearly 70,000 sq. ft. of climate-controlled manufacturing space, we provide DFM and mold-flow analysis from the outset and leverage integrated IQMS and RJG methodology to meet complex project requirements while maintaining a 99.86% on-time delivery rate.

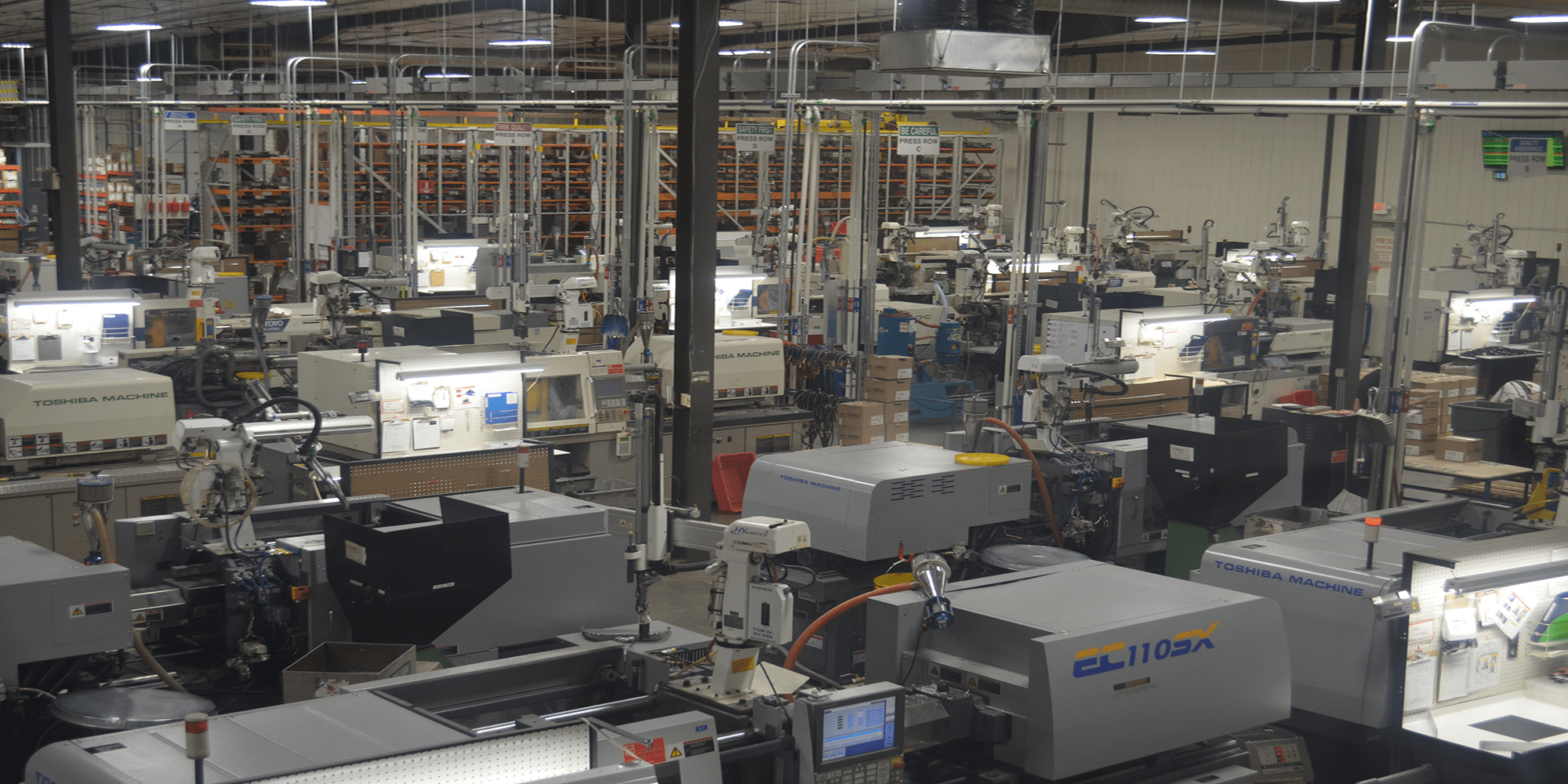

Injection Molding

With over 50 all-electric presses, we have a wide range of custom injection molding solutions serving a range of strategic markets, Vital Plastics has been focused around providing customers with a comprehensive solution to their plastics needs. As technology and markets continue to evolve we stay committed to reinvesting back into our infrastructure and expanding our resources so we can always provide the best available value in the custom injection molding supply chain. Whether our customers have simple shoot and ship type of products, or comprehensive assembly and value add opportunities we welcome the opportunity to showcase our extensive engineering and technology services.

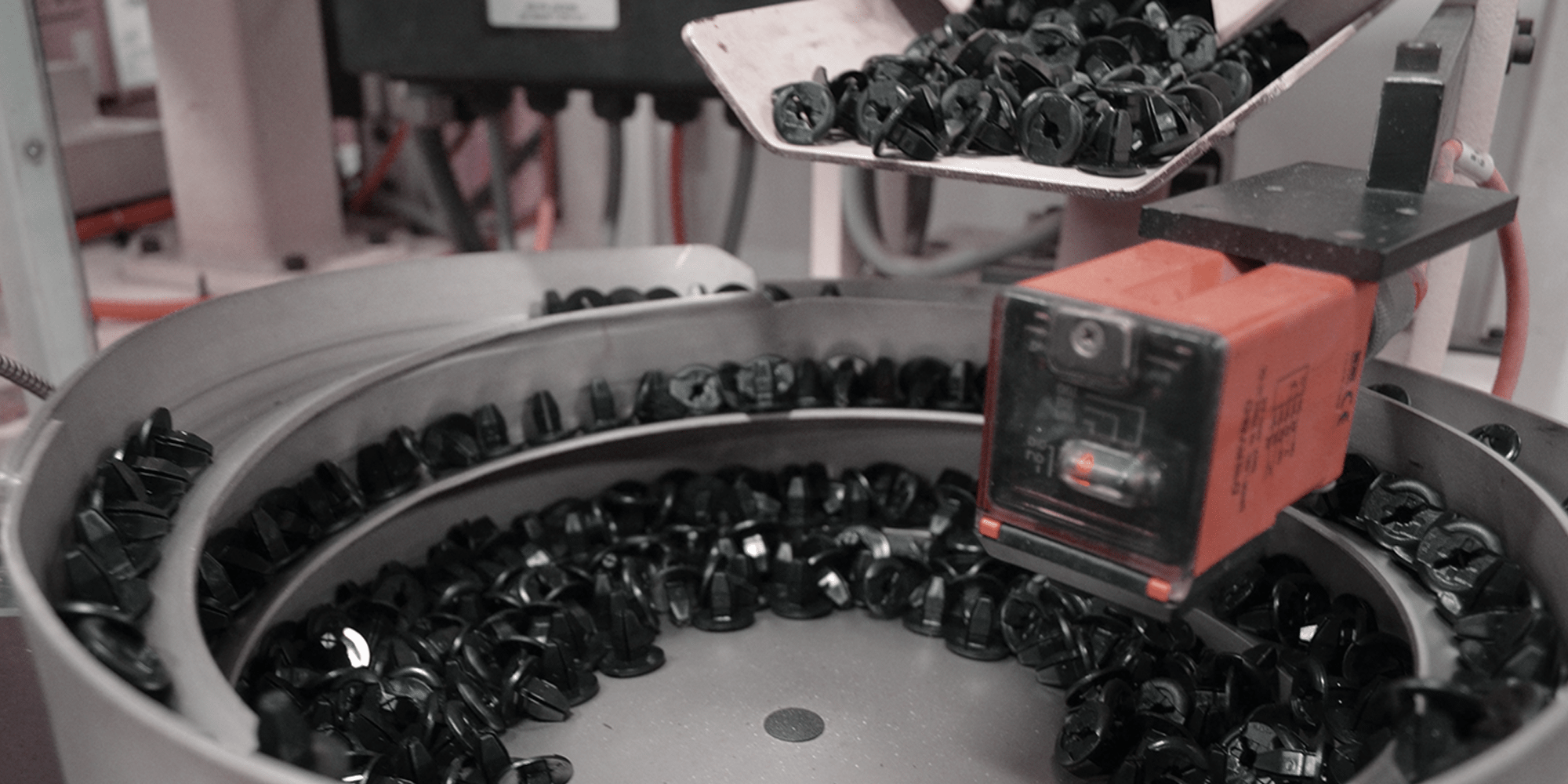

Assembly Services

Our large volume assembly services eliminate any middle men. This provides one resource and offers a cost effective solution. We utilize fully automated assembly machines we have bought or built ourselves as well as utilizing customer supplied equipment. In cases where the volume doesn’t warrant the expense of fully automated machines, we’ll utilize our semi-automatic equipment or hand-set assembly as a viable option.

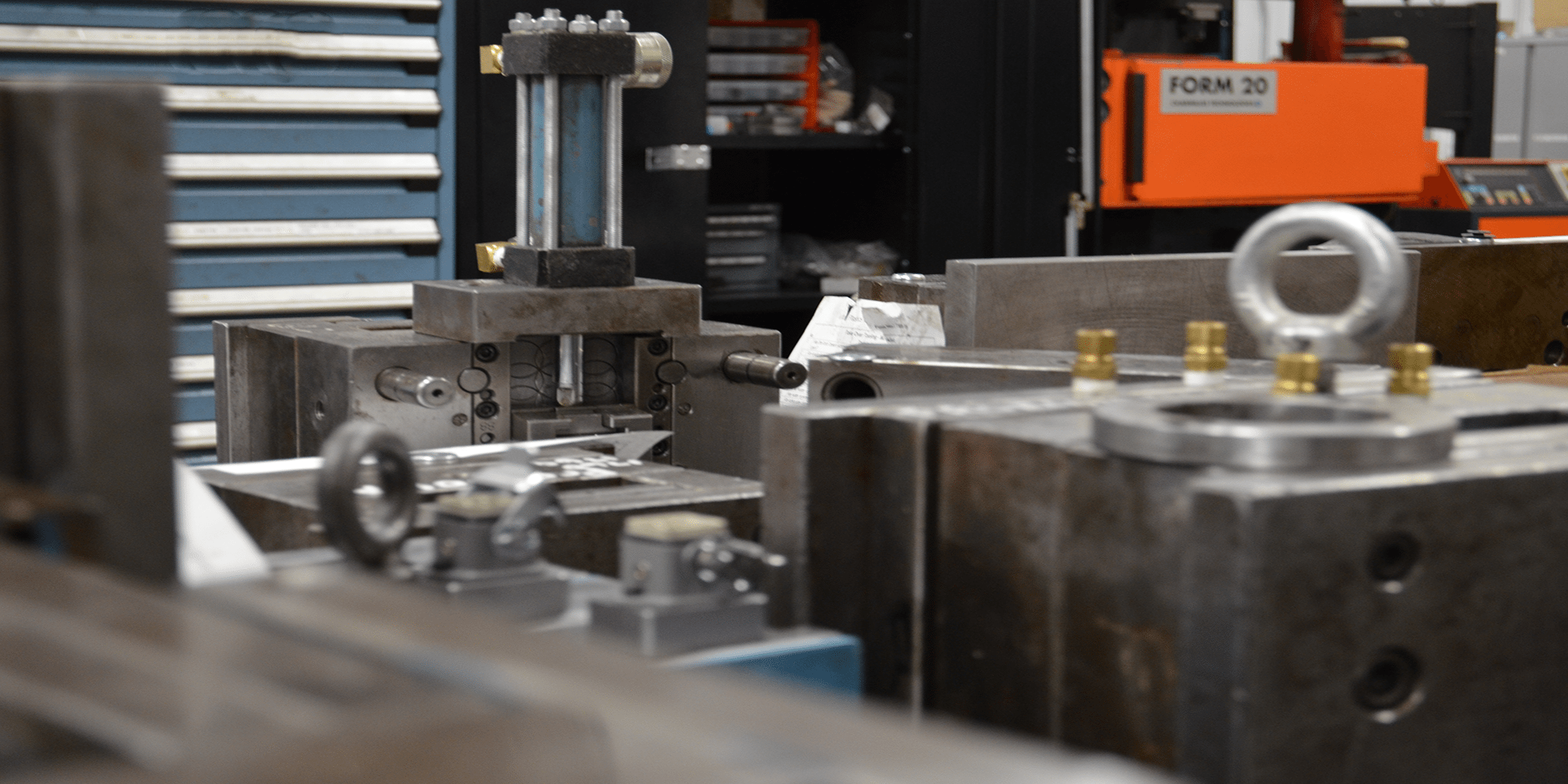

Tooling Solutions

We look forward to being your manufacturing partner on your journey to improve your efficiencies and your profitability. Our goal is to help unclutter your manufacturing floor; resulting in greater yields. With our two manufacturing facilities we are the perfect size. We’re large enough to handle your high-volume molding & assembly needs, yet small enough to focus on customer-specific requirements.